Although it is an essential part of your pool’s filtration system, your swimming pool pump will eventually need to be serviced or replaced. Mechanical seal replacement is a typical service for pumps used in pools and spas. It’s the kind of fix that could set you back a lot of cash. Learning how to do the repair yourself can save a lot of money.

Why a pump needs a seal

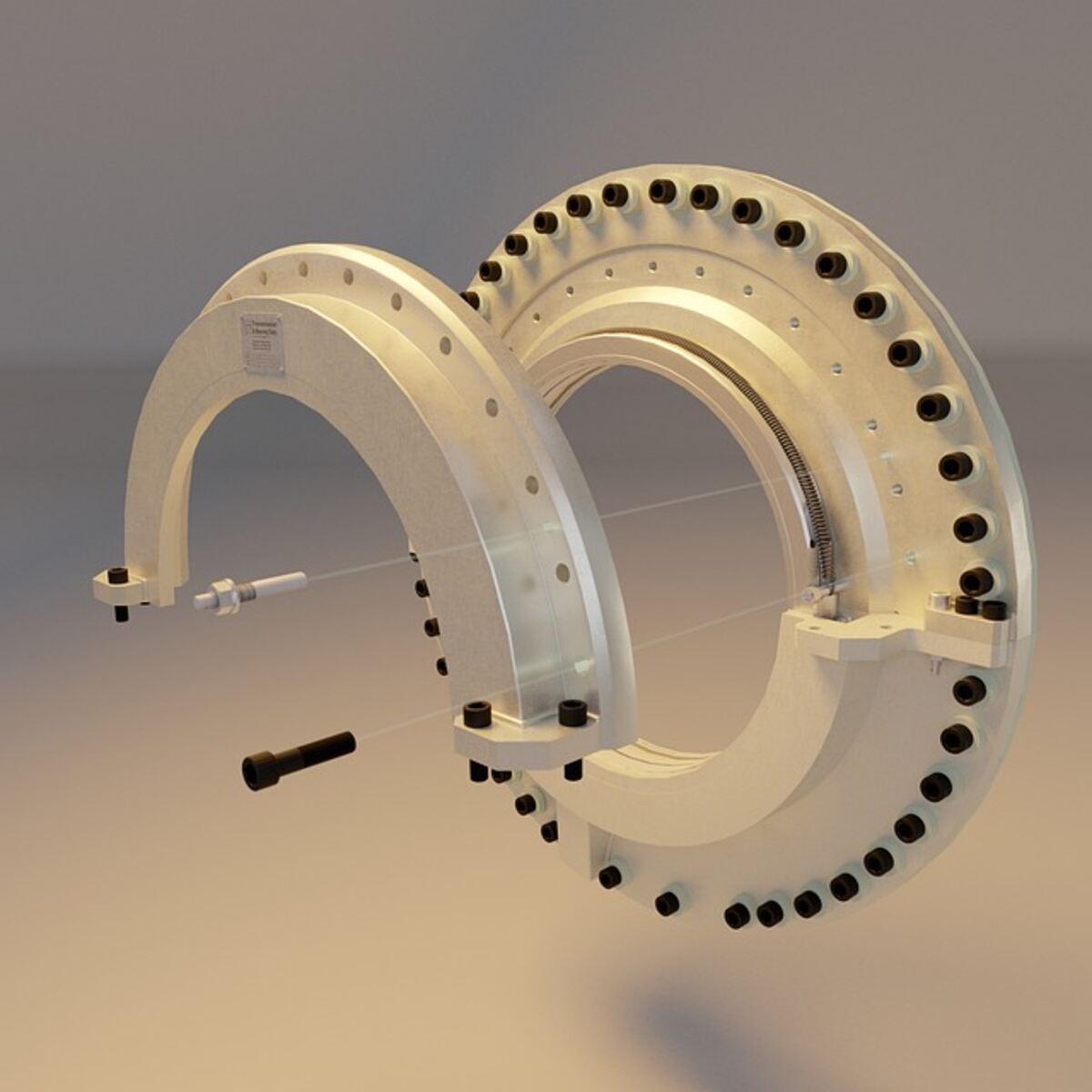

There is a shaft seal built into every centrifugal pump. These shaft seals are installed to prevent any leakage of the pumped liquid along the shaft. It is crucial to learn about the many types of mechanical pump seals. It explains the operation of a simple mechanical seal. How do I go about replacing the seal on my pool’s pump? Let me explain! The primary function of a pump seal remains the same regardless of whether the pump is used in a swimming pool or spa. And it is to seal all the holes.

Repair of a Mechanical Seal

To fix the seal, you must first turn off the electricity to the pump. After turning off the power, the main breaker must be locked. The power won’t be able to be flipped on by mistake now.

Equipment and materials required to replace the seal

A few simple tools and parts are all that’s needed to replace the mechanical seals in a pool pump. Items like these include:

A combination of open-end and ratcheting wrenches.

A replacement mechanical seal for the replacement setup.

A group of flat-headed screwdrivers.

Sandpaper made of emery cloth.

Puller for a bearing. As a means of assisting in the extraction of the pump’s impeller.

In other words, a brand new impeller. Only if the one on the pump breaks will this be required.

All new paper gasket for the volute. You can’t recycle the old one for usage again.

Either a hammer or a rather big rubber mallet.

You can get started on the repairs at last because you have everything you need.

Precautions for a Smooth Shaft Seal Replacement

Make sure the main breaker is turned off and locked out.

Turn off the pool pump by closing the drain and suction valves.

Loosen the screws that are anchoring the motor to the base.

Disconnect the flex coupling and pull the motor away from the pump.

To release and empty the pump housing, just remove the drain plug from the volute housing.

To remove the volute cover plate, undo the bolts holding it to the volute.

Remove the cover plate from the volute and loosen the blots in the pump stand. By means of reversing the bolts. The cover plate might need to be gently pried off with a hammer.

The impeller can be freed by unscrewing the bolt holding it in place with a ratchet.

Remove the pump’s impeller from the shaft. Use the bearing puller to assist with removal if it is stubborn. Check for damage to the impeller. This is the test to see if it needs to be replaced. Take care when removing the impeller to ensure it stays in good condition. The impeller should not be damaged in any way.

Once the impeller has been taken out of the shaft, the key used to secure it can be taken out.

Remove the old seal’s rotating component and spring from the pump shaft’s distal end using the screwdriver.

The next step is to take out the ceramic (the seal’s stationary component) from the volute cover plate’s seal recess. You’ll need to flip the cover plate upside down and tap the broken seal loose.

Once the old mechanical seal has been taken out of the pump for good, you may look at the shaft, the sleeve, and the seal recess to see if any of them are damaged. The pump shaft may eventually need to be replaced, but that’s a different kind of fix altogether.

Using emery cloth, water, and drying time, clean the seal recess. Remove any grime and corrosion from the shaft’s outermost end sleeve by cleaning it thoroughly.

When removing the packaging from the replacement mechanical shaft seal, take care not to scratch the newly polished seal faces. Keep the mechanical seal off of your desk as well. The faces of the pump seal are easily damaged, rendering the seal useless. That’s a leaky assumption.

Place the seal’s fixed component (the ceramic section with the black rubber cup) into the volute cover plate. Keep in mind that it must be installed in the same way as the previous one. This seal component must be fully seated in the cover plate’s seal recess, so double-check that it is there.

The pump’s rotating shaft seal must now be slid over the shaft’s enlarged end. Gently lower it until it reaches the ceramic piece’s polished face in the volute cover plate.

A slot on the pump shaft is designed to receive the impeller key.

Align the impeller’s slot with the key and slide it onto the shaft to secure it.

Blot and tighten the impeller after replacing the washer.

You may now put together the centrifugal pump for your pool.

The volute paper gasket must be replaced and then sealed with RTV silicone sealant. When fixing pumps for pools and spas, only use non-hardening silicone lube. Vaseline and other petroleum-based lubricants SHOULD NOT BE USED. Some paper and plastic gaskets can be eaten away by them, leading to leaks. After installing the paper gasket, the pump can be reassembled.

The pump housing’s volute cover plate assembly slides into the volute.

The cover’s bolt holes must be aligned.

Crookedly tighten the bolts after inserting them. This prevents the impeller from binding to the volute. housing walls and allows the cover plate assembly to slip into place.

Align the motor hub with the end of the flex coupling by reinserting the coupling into its hub and reinstalling the motor.

The motor’s holding bolts must be inserted. Make that the pump and the motor are in sync for optimal performance. Your mechanical seal will fail again if you don’t.

Turn your pool pump’s valves to the on and off positions.

The pump motor needs its electricity turned back on.

Start up the pumping system and look for leaks.

Congratulations! Changing the mechanical seal on your pool pump will save you a ton of money. Please visit my site where you’ll discover a plethora of information to assist you in the proper maintenance of your pool or spa. Simply follow the “Resource” box link.

Elkin Jones holds a CPO certification and has worked in the swimming pool industry for over a decade. He manages the daily activities of the resort’s aquarium life support and pool maintenance at a prominent Bahamas resort. Visit http://www.swimming-pool-care.com for all your aquarium filtration and life support system needs!

Elkin Jones owns all copyrights. Disclaimer: No License Granted.

Read also: What Role Does Brand Intellectual Property Play In The Globalization Of Corporations?